Go Smartly With ERP Business Software for Manufacturing Business Processes and Hold Over The Legacy

Manufacturing solutions are rounded up depending on the needs of manufacturing businesses. There are numerous business benefits to implementing manufacturing ERP software solutions. Determining with ease and a simple production cycle, where the most value and return on investment comes from for your business.

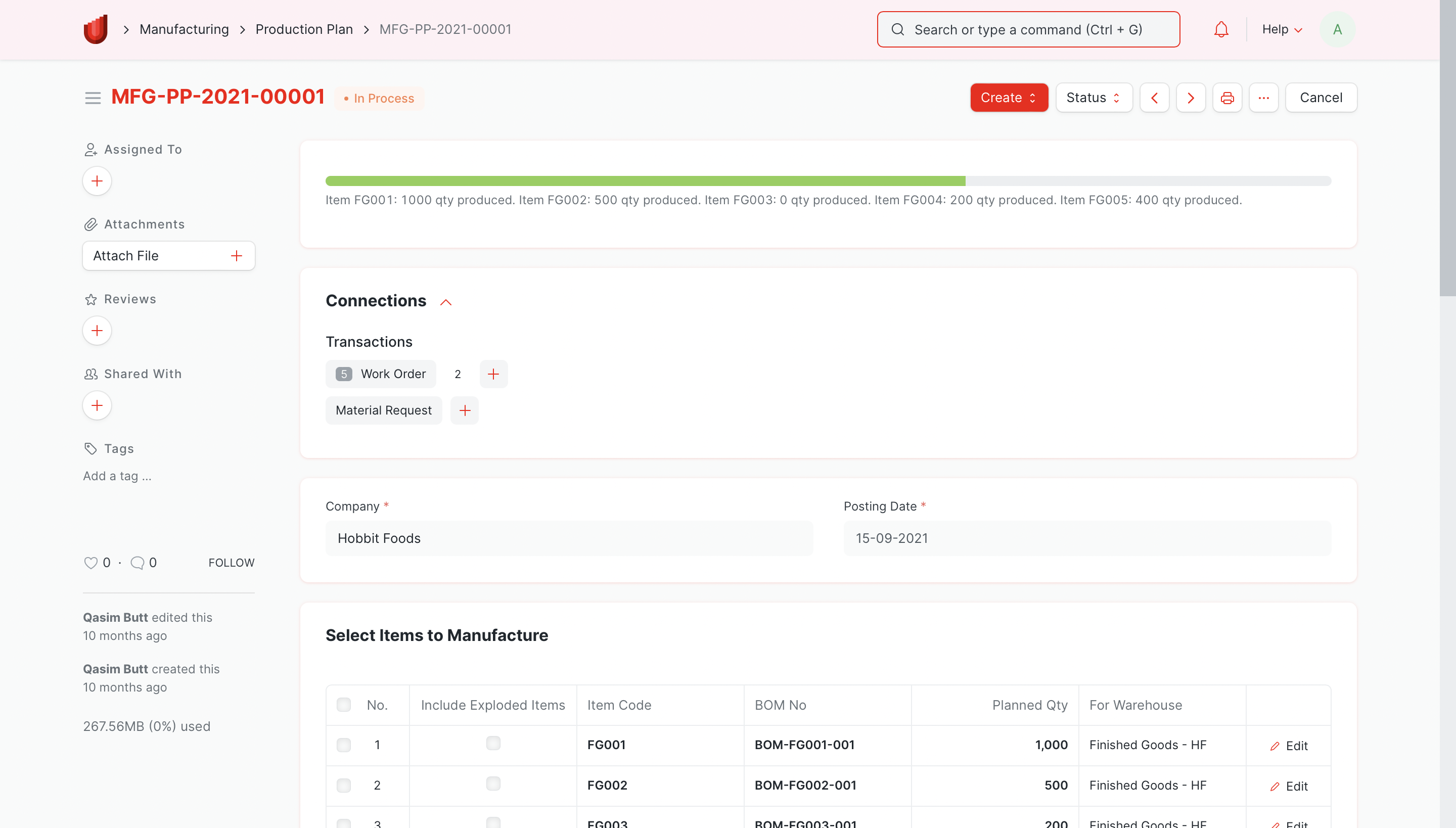

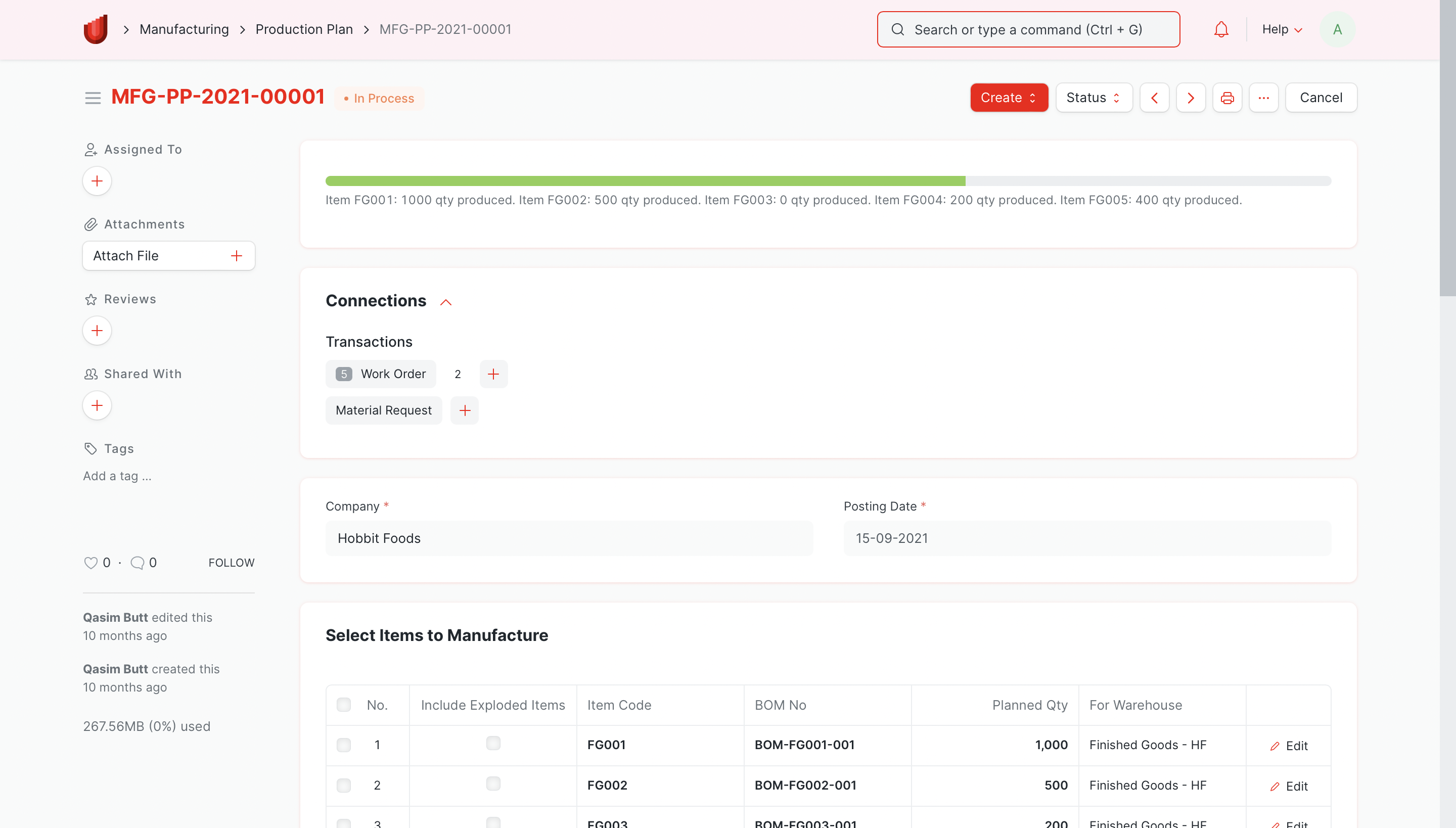

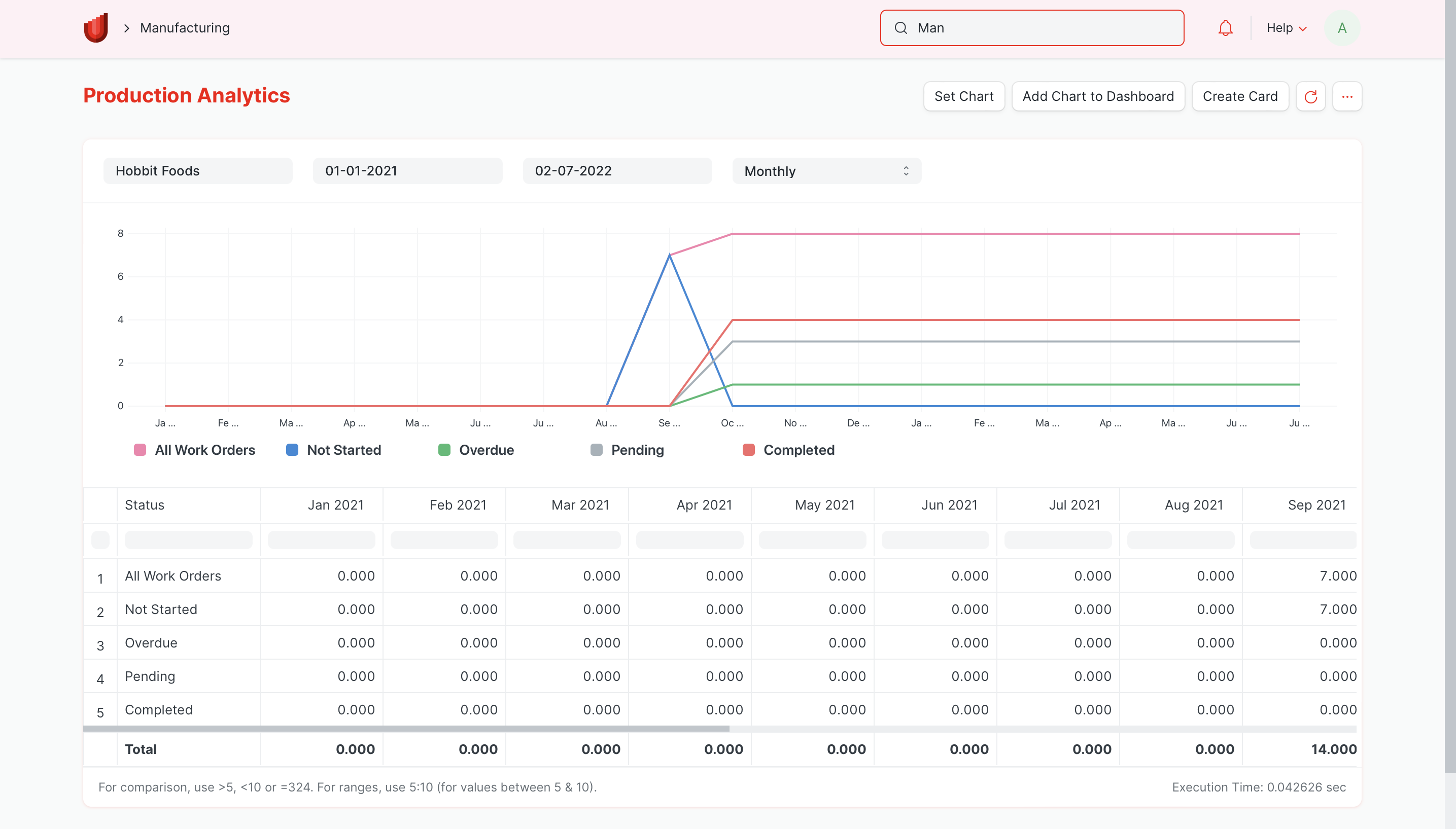

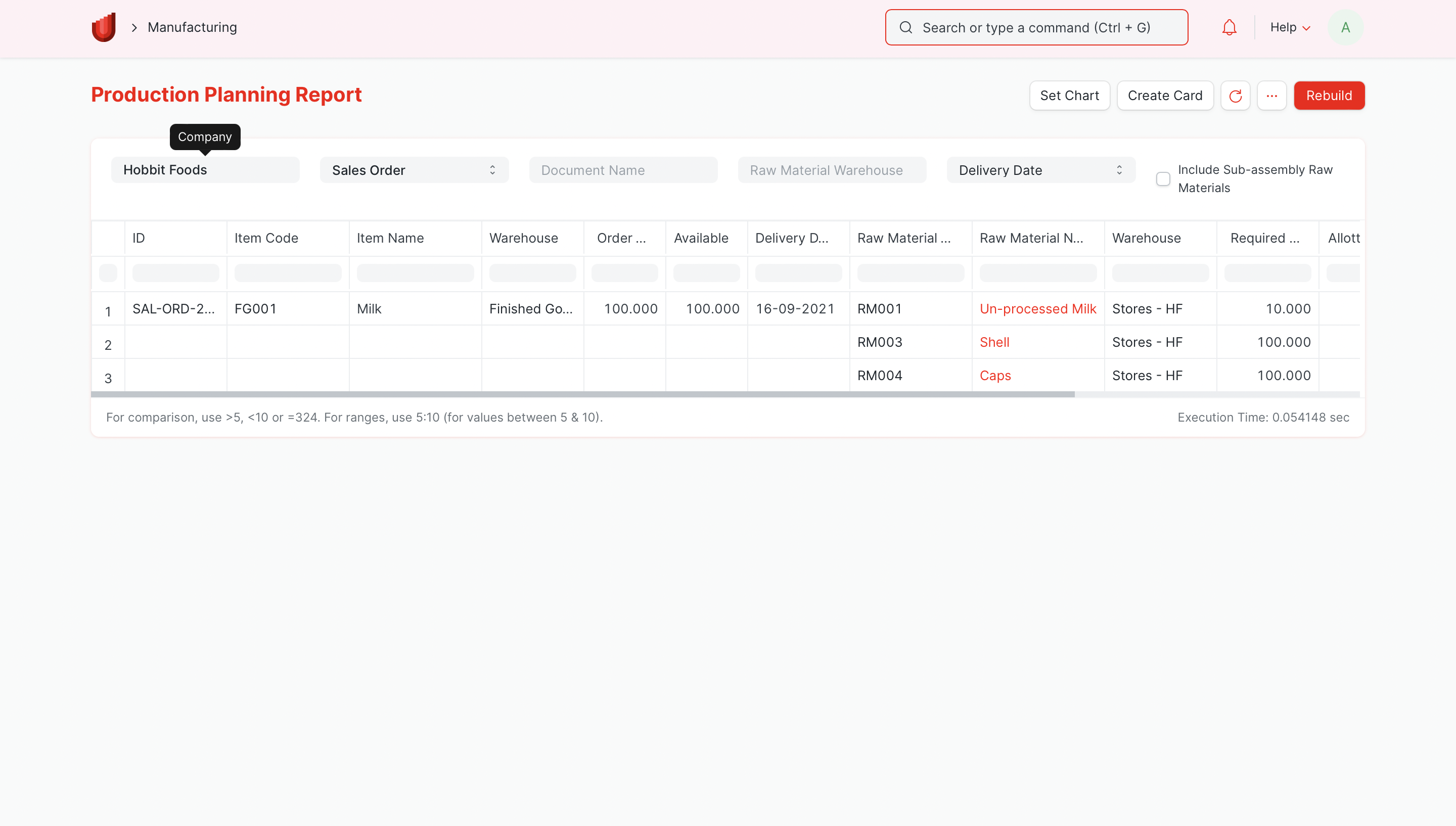

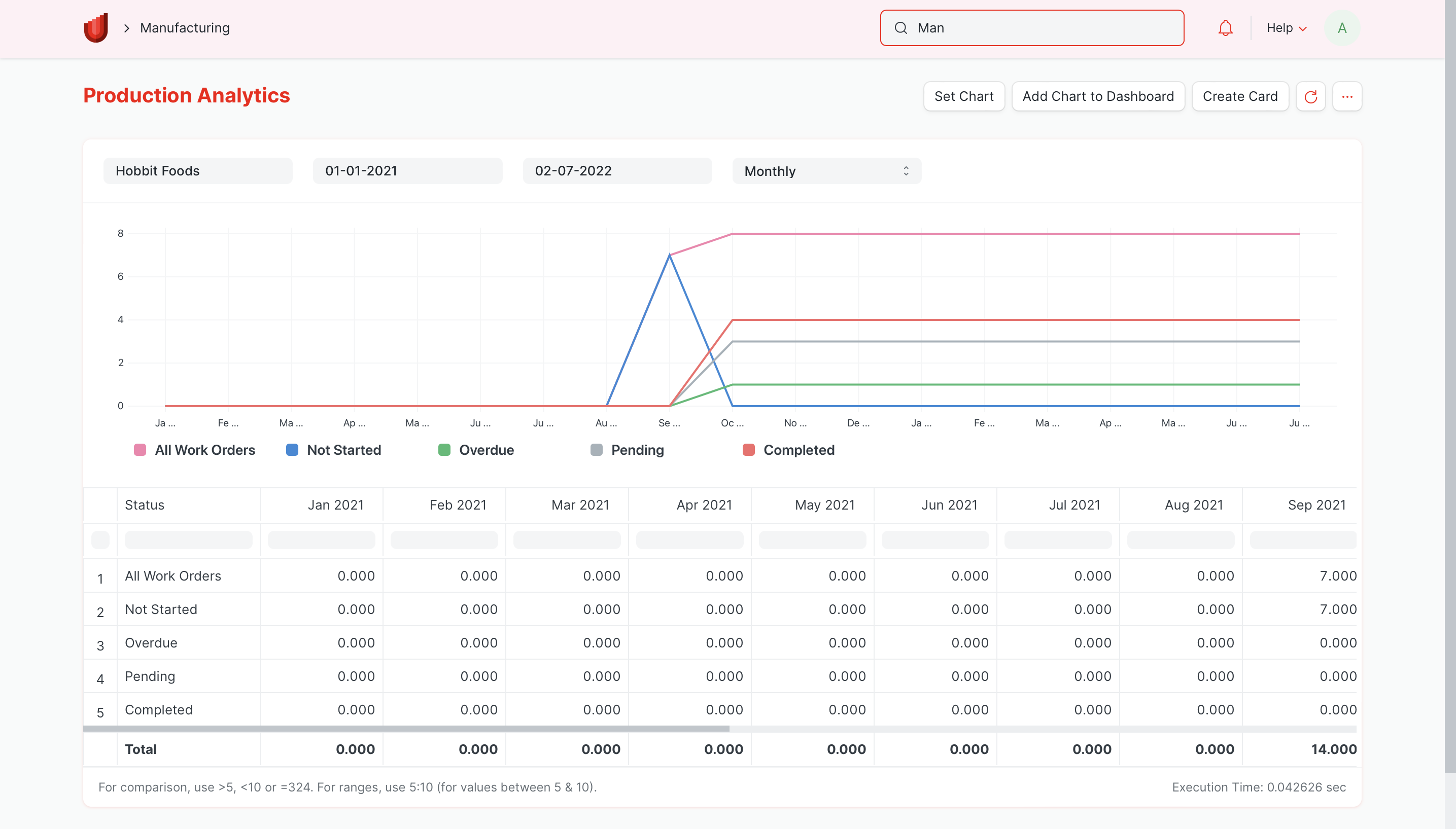

Optimize Efficiency In Production Planning and Control

Production planning and control, human resources, raw materials, and equipment/machines in a way that optimizes efficiency. ERPNU software helps manufacturers work smarter in allocating internal resources of people, materials, machines, purchasing, sales orders, and overall financial reporting in order to meet the demands of customers.

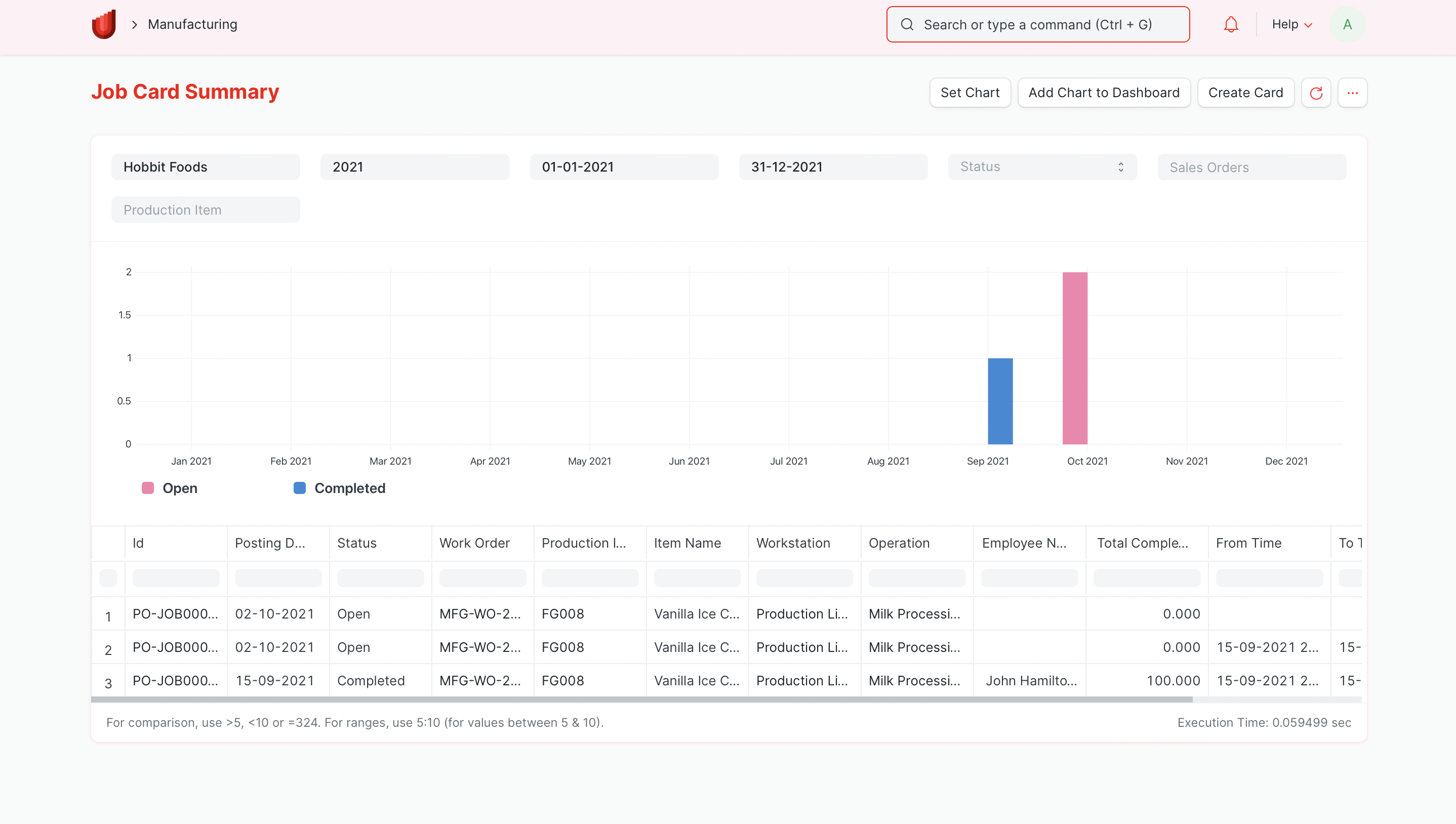

Shop Floor Control And Visual Scheduling

ERPNU’s ERP Shop Floor Management features enable manufacturers to automate shop floor operations, capture daily activities on the shop floor automatically, monitor real-time operation, improve machine & labor utilization, tracking the location of all workstations, current and pending steps of each work order, improve yield quality and achieve greater shop floor efficiency.

Subcontract Manufacturing

One of the major challenges for large companies to be ahead of their competition is by giving large orders to Subcontractors and building their network. This process of Subcontract manufacturing or Contract Manufacturing helps the corporations to deliver in the shortest possible time. With the subcontracting features of ERPNU’s, ensure quality and right quantity on time to supply raw materials, tracking on third party labor and operations. Right valuation of finished goods based on the process.

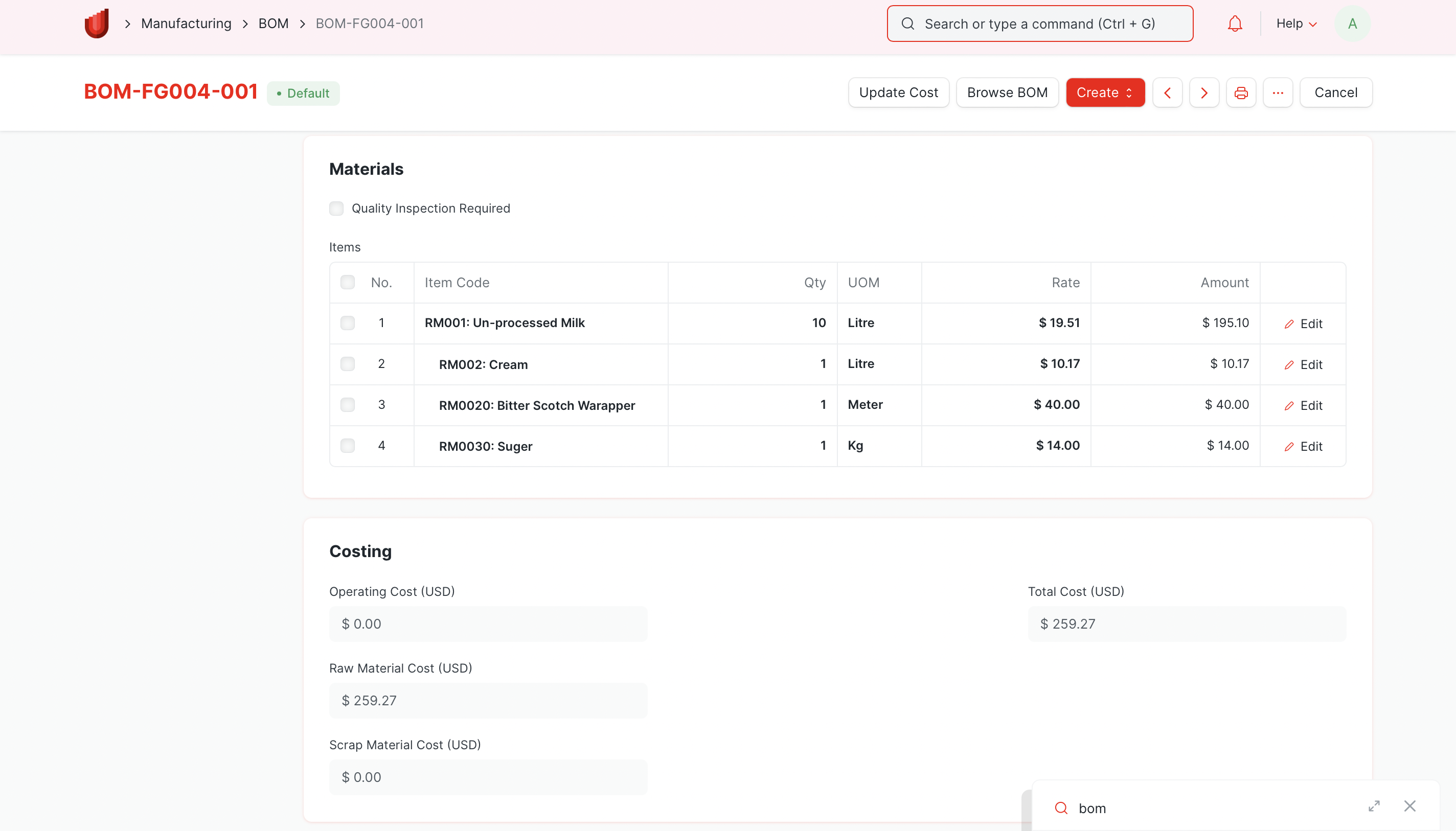

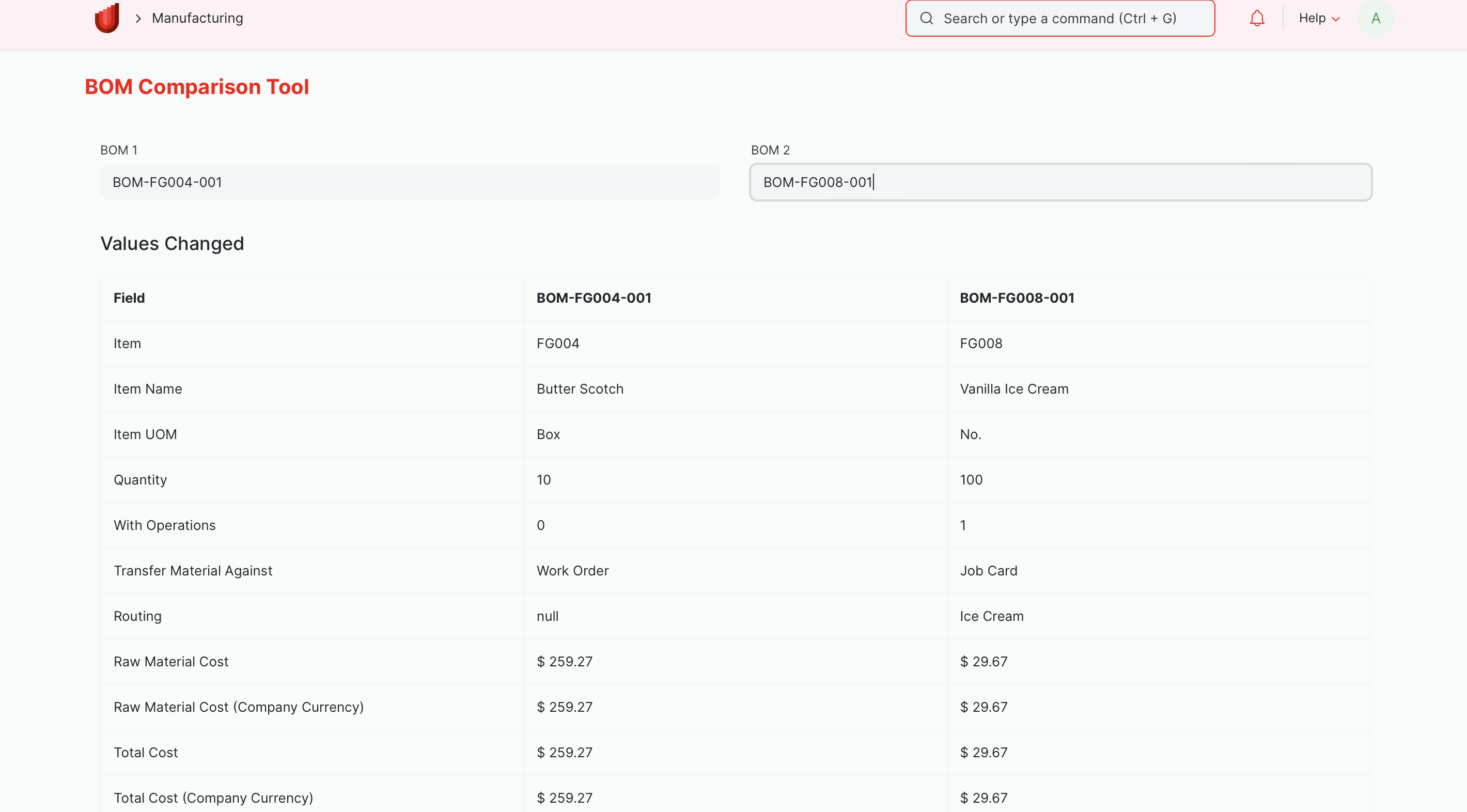

Bill of material & Work in Progress

A bill of materials (BOM) is a centralized source of information containing a list of items used to manufacture goods and lists the finished goods at the top, down to individual components and materials. ERPNU has advanced features including Item codes, part descriptions, quantities, costs and lots more.

Item Variants Management

Item variant is a version of an item with different attributes; in the manufacturing process you need to track each type of item and its variants suppose a t-shirt is an item and it comes in different colors and sizes like red, blue, green, small, medium, and large. With ERPNU’s manufacturing software an item template will be created to store the primary item and each of the variants of that primary item will store as an item variant.

Batched Inventory

ERPNU’s tool of batch inventory management system enables you to group and monitor products that were manufactured under the same conditions and used the same materials. Using inventory management software with batch code tracking, allows you to track the expiry date of items, track defective items back to the batch it was produced alongside, enabling an efficient product recall process. To make data-driven decisions quickly you can scan the item barcodes with your device camera and it’s just being such a simple process.

Stock Replenishment

Inventory replenishment processes face enormous complexities in maintaining optimal inventory balances. ERP systems alert of stock-out conditions – Inventory Replenishment alerts the buyers to potential stock-outs. ERPNU automatically creates the material request whenever the stock level goes below the reorder level.

Serialized Inventory Management

Inventory tracking through unique serial numbers to identify. ERPNU’s software offers a complete solution with customization for serialized inventory management where businesses aim to track, control and manage their inventory through unique serial numbers for greater inventory efficiency and productivity. With your device camera easily scan item barcodes and search all of your stocks very simply.

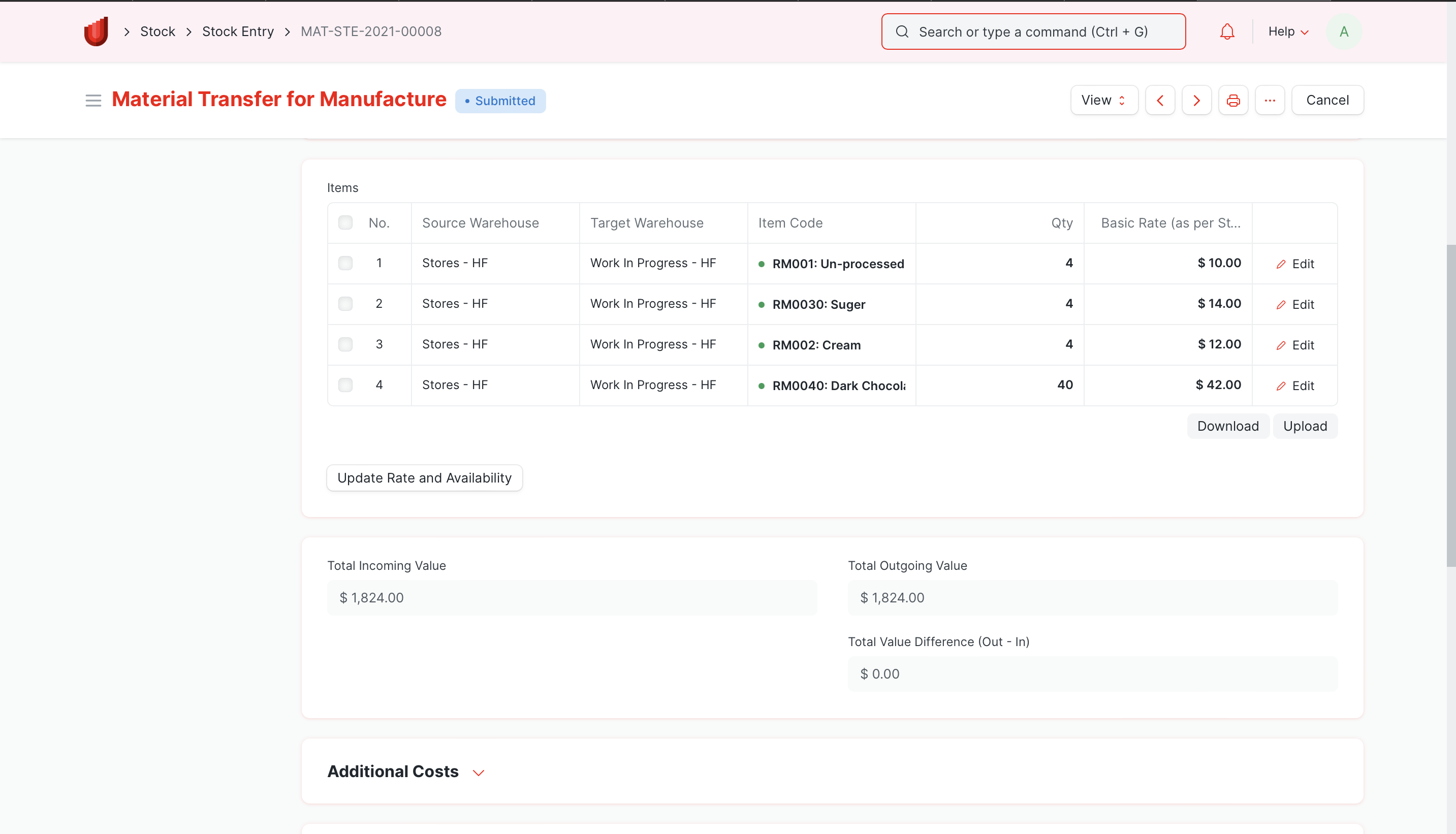

Material Management Planning

Material Management is an important process, the flow of materials, and with this process, a lot of wastage happens in terms of inventory and money. Mismanagement of material, even if they are in small numbers, is a loss for the business. The flow of materials into an organization- purchasing, production, planning, scheduling, incoming traffic, inventory control, receiving and storage. ERPNU provides a flexible and out-of-the-box approach to handle material management under one roof.

Capacity Planning

Scheduling and capacity planning are smartly integrated into manufacturing software to help your company efficiently manage production based on several factors, including labor and machine availability, suppliers, waste, scrap, errors, defects, and maintenance. ERPNU’s Cloud ERP for manufacturing includes an easy-to-use drag-and-drop scheduling and capacity planning module to help maintain and manage the schedule for a predefined period of time ( 30 days, 45 days, etc)

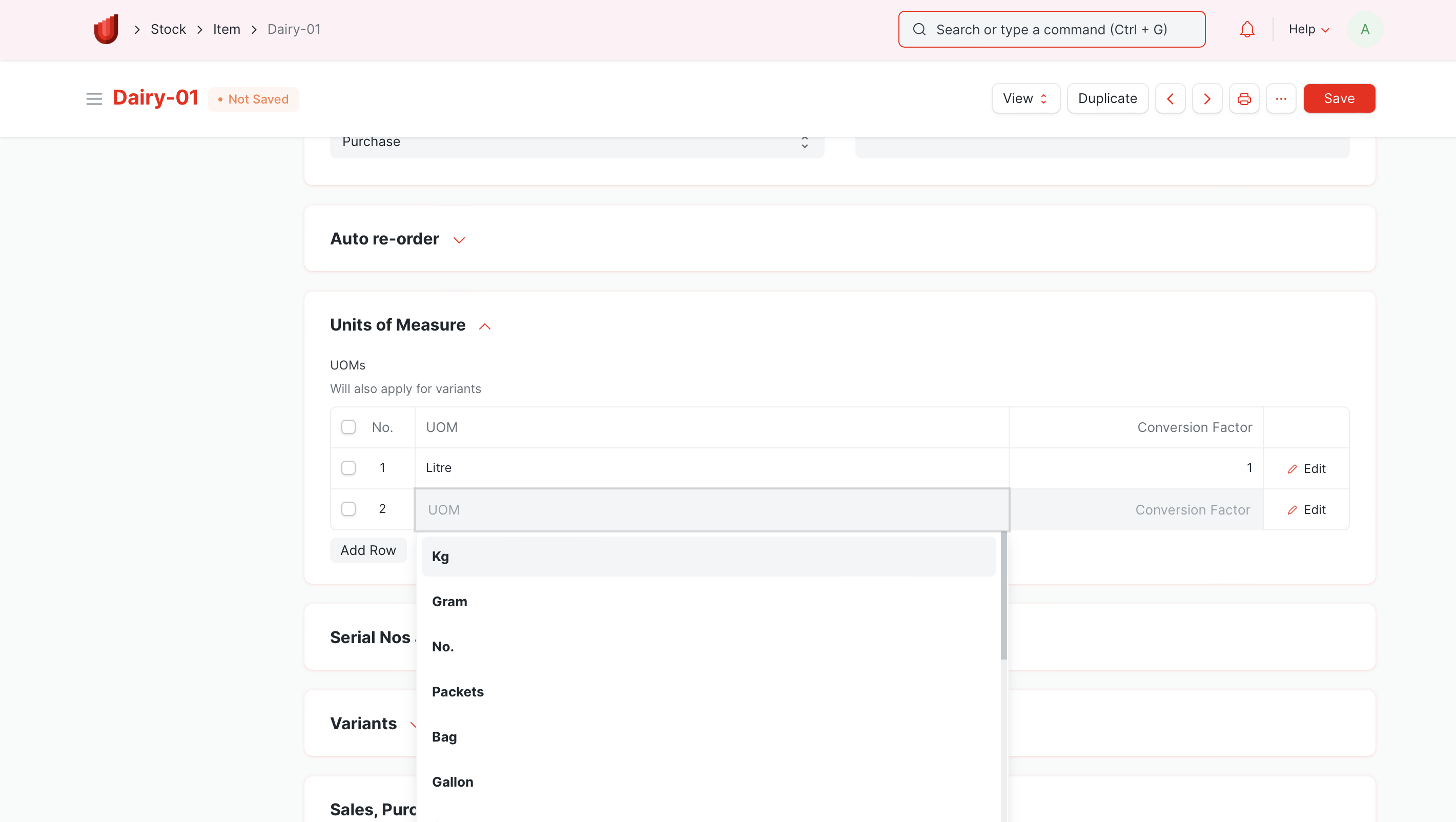

Multiple Units Of Measure

Multiple units of measure across all materials items; each individual item is bought and sold in a single unit of measure. With the changing customer demands, individual items require support in multiple units of measure for unrelated transactions. ERPNU software supports all your unit of measure needs whether it is a single unit of measure for each item across all business processes, multiple units of measure from one business process to another or for a single item within one business process or transaction.

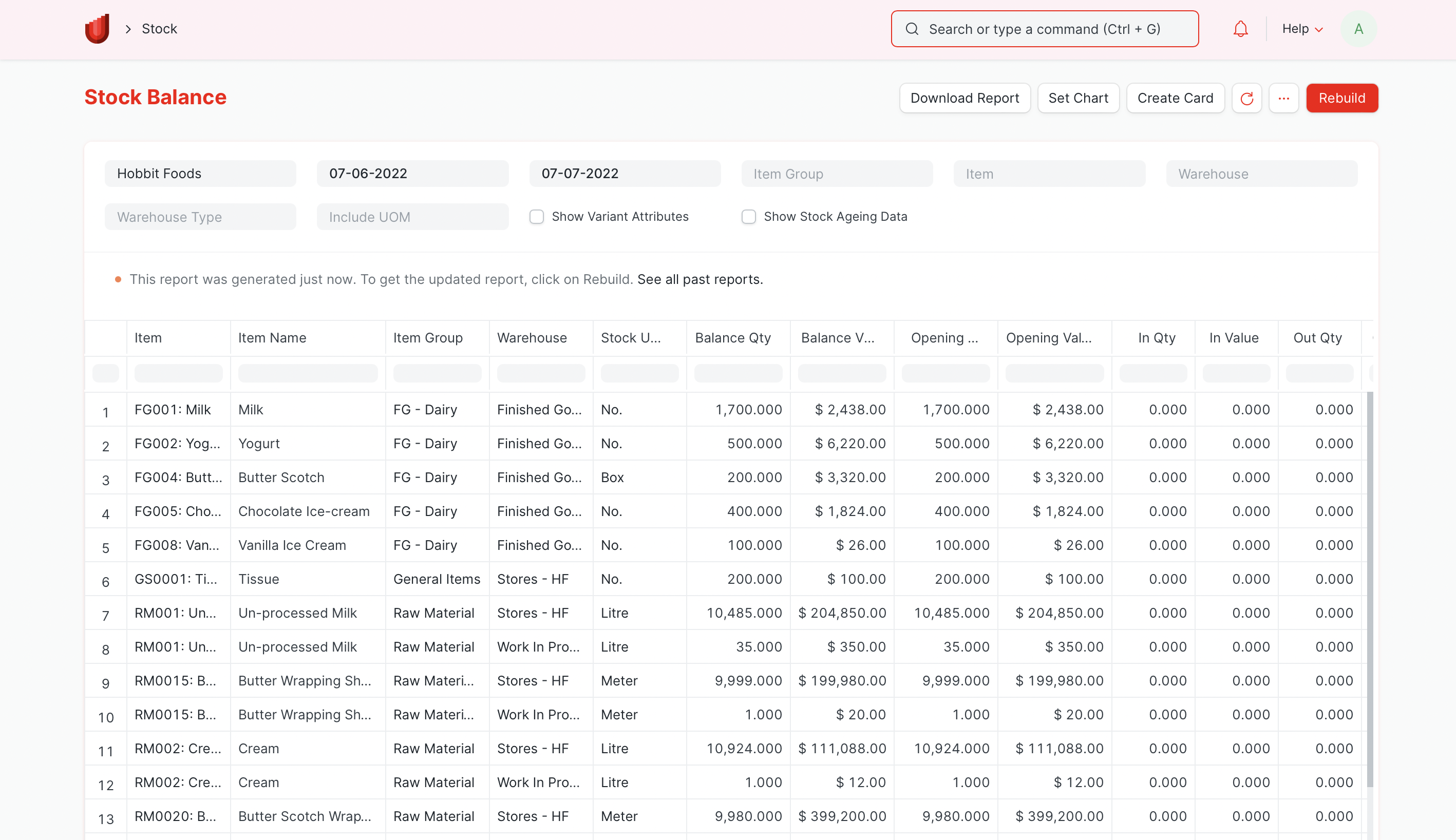

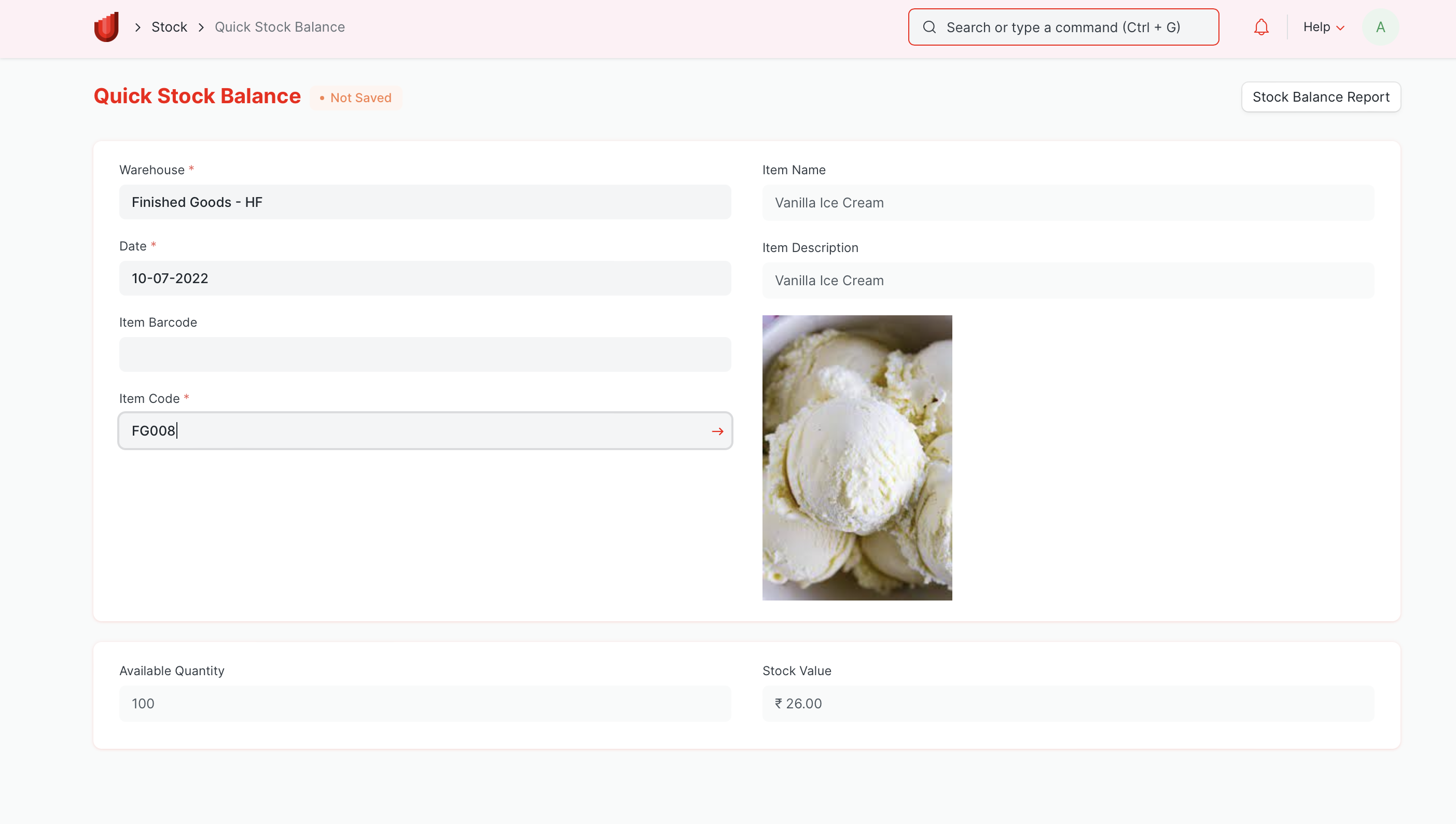

Quick Stock Balance

Scan the barcode with any device and then enter the Storage location and other details. Easily perform a stock audit and check it against stock logged in the warehouse. Fast Stock Balance report facilitates quick verification.